Super Seal™ PLC Touch

Advanced High Speed Induction Cap Sealing

Ideal for pharmaceutical packagers and operations looking for advance control, Enercon offers the Super Seal™ Touch PLC. It’s capable of sealing at ultra high line speeds with integrated cap inspection, data features, and PLC touch screen control.

Internal Intelligence

The PLC Touch model incorporates the high speed sealing capabilities of the Super Seal™ Ultra with the added benefits of advanced inspection and control options. You decide how you want to control the sealer either locally or with remote signals or network control.

Inspection System Options

- Stalled bottle

- Cocked cap

- Container rejection

- Auto start/stop

Additional System Options

- Bottle counters

- Recipe management

- Operator password protection

Application Expertise

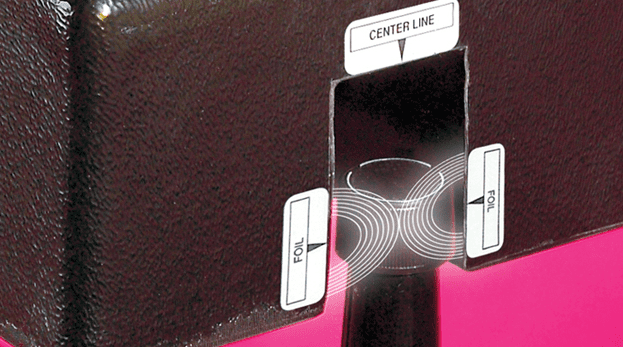

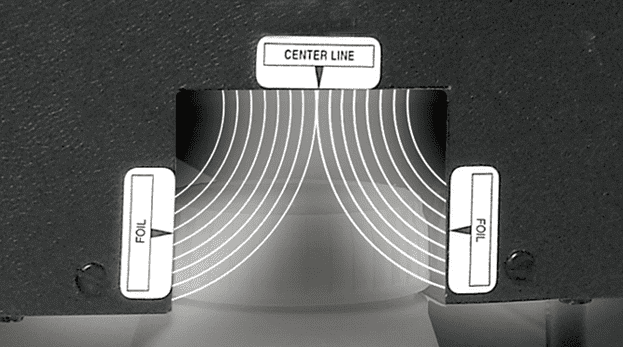

Depending on your cap and container configuration Enercon will select the sealing head that will best meet your requirements. Our engineers have develop sealing heads for every cap sealing application imaginable and are experts at optimizing sealing energy into your foil liner. If your needs ever change Enercon’s sealing heads are easily removed and replaced.

Reliable Air Cooled Design

Everyday around the world Enercon air cooled cap sealers are put to the test in every possible environment. Their success is based on an innovative design and world class components. And when you consider they require virtually no maintenance, it’s no wonder Enercon air cooled sealers have replaced water cooled cap sealers.

Ideal for Pharmaceutical Sealing

Enercon systems are designed to operate in a maximum ambient temperature of 40°C (104°F) @ 80% relative humidity, non-condensing.

KEY FEATURES For Successful Induction Sealing

-

Maximum sealing power for challenging applications

-

Intuitive touch screen simplifies setup & operation

-

Password protected settings and recipe management

-

Optional network connectivity, inspection and rejection systems

-

Stainless steel enclosure, IP55 – safe for wash down

-

Universal input voltage compatibility (200V through 240V)

THE KEY TO INDUCTION SEALING Advanced Sealing Head Technology

Enercon customers who would like to upgrade to this new technology will be pleased to learn they can use their current sealing heads with the new system.

Sealing Heads:

OPTIONS Cap Inspection Options

Foil caps should never sit idle under an active induction sealing head. Add these sensor packages to your system for additional safety:

Detects a stalled container under the sealing head and automatically turns off the sealer.

Detects container backups entering and exiting the sealer automatically turning the sealer off should this occur.

Add Quality Control to your operation with these options:

Ensures foil is present in every cap prior to sealing.

Detects if a cap is not properly seated on bottle.

Provides operators with a beacon to easily align containers under the center of the sealing head.

OPERATION:

Ejector

Simply plug-in the eJector™ along with your cap inspection system and you’re ready for seamless quality control.

Easily alerts operators of operating status from a distance.

Spare Parts Kits

Be sure your system always has backup parts. Special discounts when purchased with system.

INSTALLATION:

Mounting Options

Connect directly to your line with a floor mount or add flexibility with a mobile cart.