Super Seal™ Alpha, Supra & Ultra

Induction cap sealers for low, moderate and high speed packaging lines

Enercon Super Seal™ cap sealers are industry workhorses for production line packaging. Leading packagers select Enercon’s air cooled cap sealers for their productivity and reliability.

Four Production Ready Designs

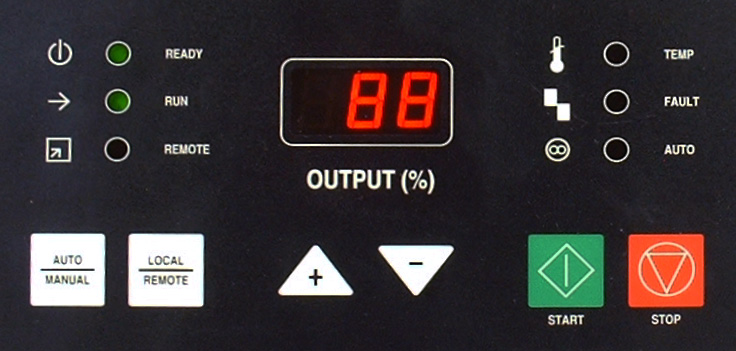

Sharing the same innovative design concept featuring microprocessor control, self protective circuitry, and soft start to prevent surges. Stainless steel enclosures are safe for wash down and the cap sealers require virtually no maintenance. The Super Seal™ series provides a simple operator interface with power levels and LED indicators. Cap sealers also offer remote start and stop control, inspection and rejection, flashing light indicator and computer interface options.

- Super Seal™ Alpha - low to medium speed lines

- Super Seal™ Supra - medium to high speed

- Super Seal™ Ultra - highest speed lines

- Super Seal™ PLC Touch - advanced operations

Inspection System Options

- Enercon e-jector™

- Stalled Bottle Detector

- High/cocked Cap Detector

- Auto Start/Stop

Air Cooled Design for all Climates

Enercon pioneered the development of air cooled cap sealers over twenty years ago. The technology offered new standards of reliability and ease of use, and quickly replaced water cooled cap sealers. Today, high speed production lines around the world in North America, Saudi Arabia, Egypt, Kenya, Venezuela, Thailand, Malaysia & India rely on Enercon for reliable induction sealing performance.

Sealing Heads Matched for your application

Key to induction sealing efficiency is ensuring the sealing energy is optimized for the application. Enercon offers numerous sealing head designs that focus the induction sealing energy on the foil induction liner. In most cases a single induction sealing head will handle your scope of cap and bottle configurations. And when your applications require more than one sealing head you’ll be pleased to know they are easily interchangeable.

KEY FEATURES For Successful Induction Sealing

-

Intuitive touch screen makes setup & operation simple

-

Supervisory password protection with operator lockout

-

Recipe management, remote start/stop and remote power control

-

Optional network connectivity, inspection and rejection systems

-

Stainless steel enclosure, IP55 – safe for wash down

-

Universal input voltage compatibility (200V through 240V)

-

Designed for quick change over

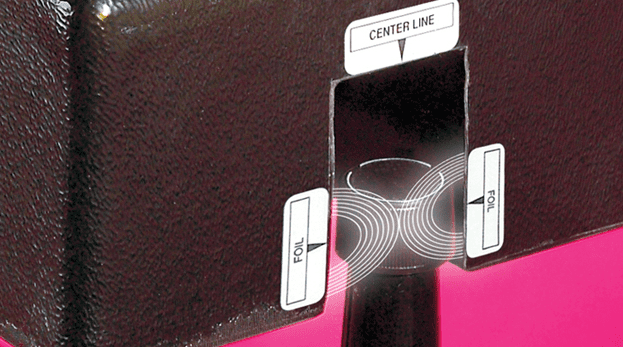

THE KEY TO INDUCTION SEALING Advanced Sealing Head Technology

The key to induction sealing success and efficiency is optimizing the available power by effectively transferring it to the foil liner.

Enercon’s engineers have mastered the science of sealing energy with the development of an assortment of unique sealing heads.

The Super Seal™ Touch offers a unique All-in-One sealing head which seals a range of cap sizes from 35-120mm.

Sealing Heads:

OPTIONS Cap Inspection Options

Foil caps should never sit idle under an active induction sealing head. Add these sensor packages to your system for additional safety:

Detects a stalled container under the sealing head and automatically turns off the sealer.

Detects container backups entering and exiting the sealer automatically turning the sealer off should this occur.

Add Quality Control to your operation with these options:

Ensures foil is present in every cap prior to sealing.

Detects if a cap is not properly seated on bottle.

Provides operators with a beacon to easily align containers under the center of the sealing head.

OPERATION:

Ejector

Simply plug-in the eJector™ along with your cap inspection system and you’re ready for seamless quality control.

Easily alerts operators of operating status from a distance.

Spare Parts Kits

Be sure your system always has backup parts. Special discounts when purchased with system.

INSTALLATION:

Mounting Options

Connect directly to your line with a floor mount or add flexibility with a mobile cart.