Corona Treatment for Blown and Cast Film Lines

Pretreat films prior to converting

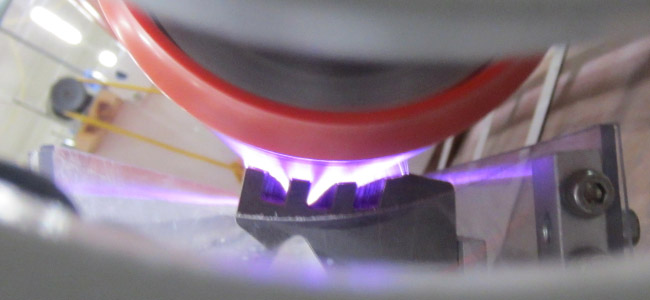

Film extruders use corona treaters to increase a film’s surface energy at the time of extrusion. This pretreatment process enables the film to be later converted by printers, coaters & laminators.

Enercon engineers will custom design a system to meet your specific application requirements. Corona Treatment options include a full range of fixed width, lane and pattern corona treatment for all types of films.

In most cases for blown and cast film operations Enercon’s application team in India recommends metal electrode systems with high capacity covered ground rolls.

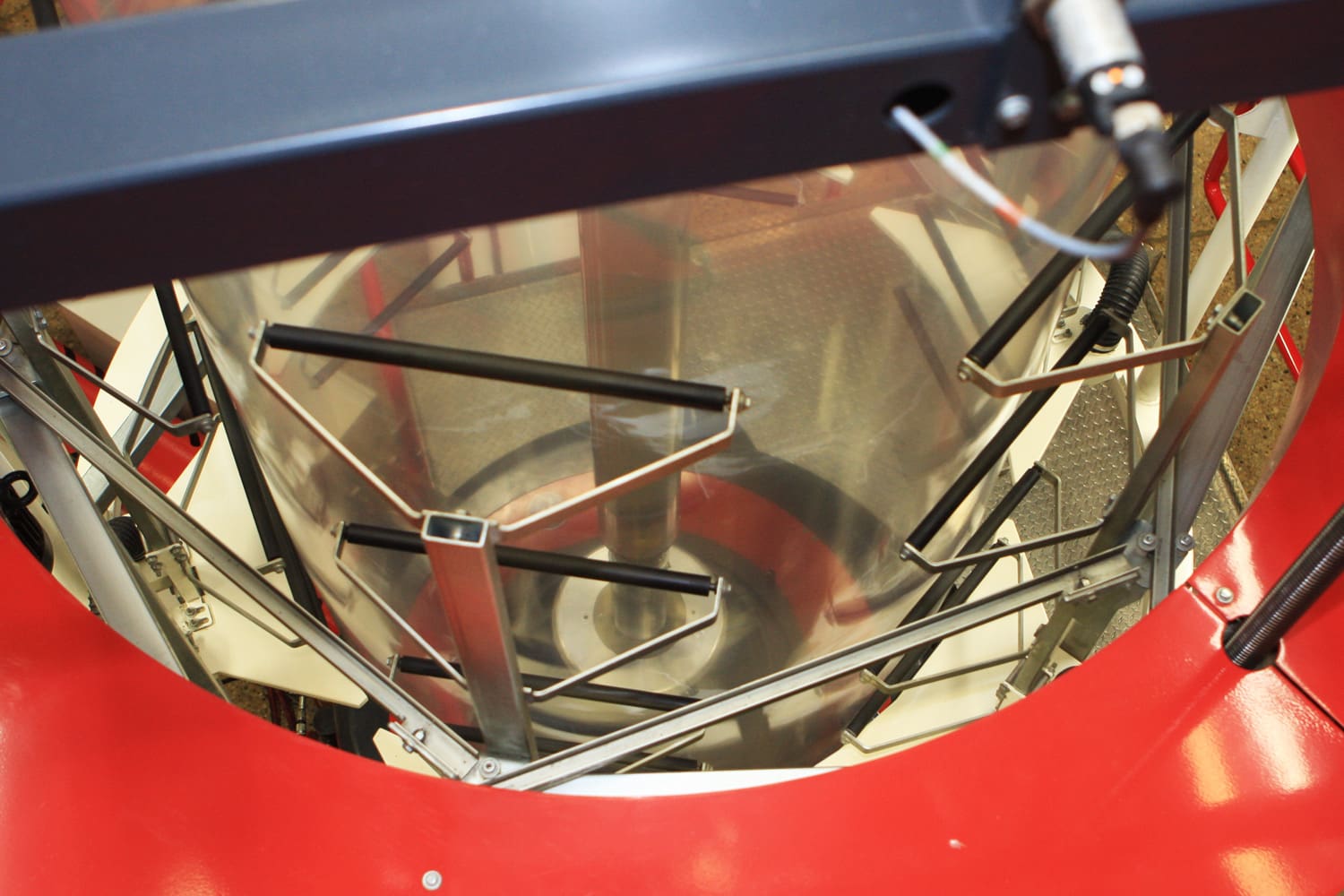

Enercon offers fixed width and segmented metal electrodes for blown and cast film applications with ground roll options to meet your operation’s specific needs. The treater’s unique electrode assembly design removes ozone from the work area, pivots out of the way for splices and enables cleaning in place without the need to remove the electrode assembly.

Enercon Unique Offerings Blown & Cast Film Surface Treating

-

Agricultural film

-

Animal feed packaging

-

Construction film

-

Food Bags & Pouches

-

Freezer bags

-

Industrial film

-

Laminating film

-

Lidding film

-

Meat packaging

-

Medical film

-

Pouches

-

Produce packaging

-

Protective film

-

Shipping materials

-

Wrapping materials