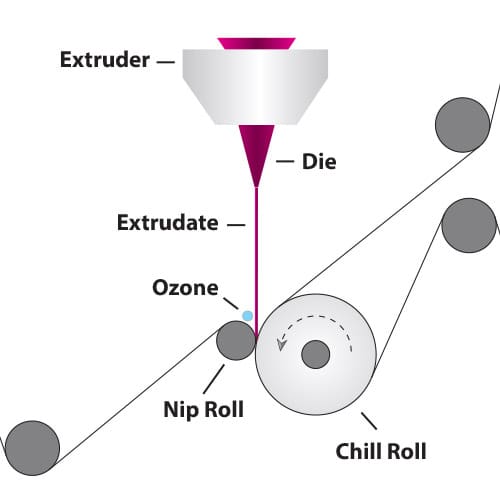

Ozone Generator For Improved Extrusion Coating Performance

Enercon’s Ozone Generators are engineered to improve extrusion coating performance and efficiency. The use of ozone in extrusion coating applications may provide significant benefits including the use of lower extrudate temperatures, reduced air gaps, faster line speeds and improved adhesion.

Several models are available that deliver high ozone concentrations at minimal power levels with specially-optimized dielectrics and high power densities. Contact Enercon to learn more.

Enercon systems are designed to operate in a maximum ambient temperature of 40°C (104°F) @ 80% relative humidity, non-condensing.

KEY FEATURES For Successful Extrusion Coating

-

Ozone Generator Designed for Extrusion Coating

-

Improve Bond Strength

-

Enable Lower Extrudate Temperatures

-

Reduce Air Gaps

-

Achieve Higher Line Speeds